It was hot at the Dairy Aire launch this weekend. 103°F, with cows.

What weather forecast is that? The cattle packed into the nearby Harris Ranch pens literally create local fog as they sweat into dusk. Mix with a little methane, and you get Dairy Aire.

Here was one of my favorite shots... 2.25 seconds after liftoff... screaming into the air, the big, fat Thumper rocket suddenly ruptured overhead:

It was part of lineup of ten M-size motor launches (the largest you can launch in California), and this gas-passer had a bit of a hiccup.

There's something about these nitrous oxide rockets that leads to some spectacular mishaps...

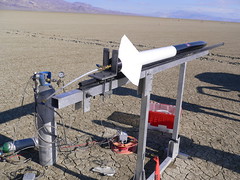

Here's a great example... the saga of Jeff's huge hybrid rocket.

This shiny rocket has a huge tank for 200 lbs of nitrous oxide (between the black sections) and a combustion chamber with 28 lbs of HTPB rubber... for a R10000 long-burn motor. Just loading the nitrous takes 40 minutes.

It's a work of machining beauty, but it blew up into tiny bits at BALLS13, so the hydraulic lift and liquid-fuel-pumping pad had to be rebuilt, as well as a shiny new 22'-tall rocket.

At BALLS16, it screamed up to Mach 3 and exploded (Jeff's photos).

This was the forth attempt at BALLS17, and it's even more amazing...

But, after loading the nitrous tanks, and a wonderful launch, the combustion chamber seal failed, and hot gasses burned out to the side:

And then $1,200 of N2O vented out:

Ground diagnosis was that hot gasses escaped up and out of the combustion chamber due to a failure of a simple phenolic liner. From other photos I took, I can tell that the fancy carbon fiber upper section zippered badly when the drogue chute deployed at high speed.

I'm sticking to solid motors for now.

I like the 4th photo- the launch shot- it's a nice use of foreground to create context for the action.

Ooh neat, I have lots of questions:

What are the advantages of using a nitrous based system like this? Longer impulse with slower burn, IE slower accel to achieve the same altitude?

Does the nitrous enter the chamber as a liquid or a gas? What does the combustion chamber look like shape wise?

I notice a lot of these rockets to seem to be built with significant altitude in mind; is there much attention paid to the change in atmospheric pressure when designing combustion chambers?

Why HTPB rubber in the chamber? Used as an ablative?

What sort of payload was inside of this rocket? What's typical?

What do they use for control solenoids of the nitrous? Pillaged Parts from automotive applications?

Spiv - I have not flown a hybrid, so I am out of my element here. (in this case, I focus on the art of photographing their failures =)

In general, my understanding is that they are cheaper and unlike solid rockets, can be throttled back or even shut off mid flight (for safety)

Jeff's big project is a bit unique. The CATO picture on top is a HyperTek hybrid, and they use thermoplastic fuel grains and NOX oxidizer. http://www.hypertekhybrids.com

Let me ping a friend on your pressure / chamber design question.

And here is a thoughtful response from my rocket mentor, Tom from

http://www.rocketmavericks.com

(my only addendum would be that "payloads" may include videocams and GPS/RF tracking and fun stuff, but not serious payloads as in the aerospace sense)

What are the advantages of using a nitrous based system like this? Longer impulse with slower burn, IE slower accel to achieve the same altitude?

> The primary reasons for nitrous systems are cost and thrust control. Solid propellant motor technology to date is limited to all or none thrust. You light it, you buy it. Unless you use a pintel, there is no way to control the thrust rate on a solid motor without inducing stability problems that lead to a cato. There is a group of us that have come up with an electrically controllable solid propellant, but that is still under wraps with lots more work need to make operable.

Liquid motors have much higher costs associated with them primarily because of the special pumps required to keep feeding oxidizer and fuel into the high pressure motor chamber, and dealing with pumping of LOx (Liquid Oxygen) and having it available at the launch site is costly and dangerous for most hobby uses. Nitrous Oxide is cheap, more stable than LOx and you can simplify the costs of the rocket motor design by simplification of not needing cryogenic booster pumps.

Does the nitrous enter the chamber as a liquid or a gas? What does the combustion chamber look like shape wise?

> Gas. Generally, the chambers are shaped to maintain the maximum pressure at the lowest weight, so they have spheriodial shape, but there is nothing that says it has to have any particular shape. I have seen spheres, tubes, etc. You do not want any discontinuities in the flow, so any sharp angles are generally not a good thing as they impact stability and flow to the convergent portion of the nozzle. A spheroid handles the highest pressure distribution of the smallest surface area. The biggest challenges with cylinders are the closures, which is where most failures occur, unless you have a fuel air ratio instability which leads to a detonation. The nozzle is the key to the motor thrust. All the chamber does is convert chemical potential energy into pressure potential energy. Thrust is produced by conversion of potential energy into kinetic energy thanks to uncle bernoulli.

I notice a lot of these rockets to seem to be built with significant altitude in mind; is there much attention paid to the change in atmospheric pressure when designing combustion chambers?

> Yes, when you consider the nozzle. If your nozzle is fixed in geometry, then you have to look closely at how much the divergent portion aft of the throat expands the fluid. Ideally, you want the exit pressure to match the ambient pressure. If you under expand, you loose pressure thrust by loosing velocity expansion, if you over expand, then you create induced drag and loose thrust that way. Many NASA rockets have a divergent nozzle section that adjusts, because as you ascend, and the pressure drops you really should change the shape of your divergent section of the nozzle to maximize thrust. You can also control motor operating pressure by throttling back, assuming you have a throttlable propellant.

Why HTPB rubber in the chamber? Used as an ablative?

> No HTPB is the fuel. NO is the oxidizer.

What sort of payload was inside of this rocket? What's typical?

> No payload. Xprize winners fly people in the White Night and White Night 2. Most of these experimental rockets are just that. If you are experimenting this the rocket, you donât want to commit to a payload. Payloads are expensive and they will be destroyed with an unknown experimental rocket technology that goes badly.

What do they use for control solenoids of the nitrous? Pillaged Parts from automotive applications?

> Depends upon the implementation, but typically, a gas solenoid valve is used. There are no pumps in these designs. The tank is pressurized above the operating pressure for the motor, which is calculated as part of the design. That way when they are relieved into the combustion chamber, as the chamber goes to full pressure, they do not starve the motor of oxidizer. Typical failures are due to ice forming in the adiabatic expansion of the NO, creating instability in the fuel ratio and oxidizer flow, which can cause an explosion. Also, case failures are an issue in this case due to insulation issues with the thermal design. Most solid propellants act as an insulator for the motor as the propellant burns on the surface. The HTPB fuel grains do not perform as well, and there are different thermal characteristics with the combustion in larger motors that you need to account for.

Thanks Steve!

I'm more familiar with the LH2/LOX setups used in SSME's, but it's such a different scale I've never really considered a liquid fueled system for small applications like this. In SSMEs the "combustion chamber" is, effectively, a short cylinder leading into the bell. I remember seeing spheroids and frustum shaped chambers in older designs (All mixing is done in the injector, and monitored prior to burn for ox/fuel ratio so as to be adjusted "very very quickly" (you can imagine: lagging behind on adjustments for those babies would be a pretty bad day. The bell itself is brazed together and wouldn't take much of a lean mixture before cnn-moment-cato).

I've always wanted to build a liquid rocket motor, but have basically been stopped by the thought of dealing with multi-stage turbine pumps and condensation of h2 and o2. Nitrous is easy, I deal with that for car stuff fairly often. You happen to know where I can see some designs used in nitrous/htpb rockets?

So fuel mixture is handled entirely by the flow rate of oxidizer, and the htpb is just let to burn in its environment at will? How do they monitor mixture?

Sorry for the endless questions; this is very interesting to me :)

I've always wanted to build a liquid rocket motor, but have basically been stopped by the thought of dealing with multi-stage turbine pumps and condensation of h2 and o2. Nitrous is easy, I deal with that for car stuff fairly often. You happen to know where I can see some designs used in nitrous/htpb rockets?

thanks....steve